In the Italian scenario, many companies are converting part of their production into devices to deal with the emergency, continuing to develop projects for the community that can improve situations of coexistence with Coronavirus. Negri Bossi who since April 9, 2020 has been using two injection machines to produce masks for the community through the help of the Lombard Civil Protection to counter the spread of COVID‐19, the most serious pandemic of this beginning of the century, is working in collaboration with another all‐Italian company: COMPLASTIC Srl.

The company born in 1984 from the business idea of Salvatore D’Alise today has a 2000 sq. m plant in the Maddaloni Valley in the province of Caserta and specialises in thermoplastic moulding and patented coinfection mainly for the Automotive, Food sectors, Textile and Personal Protective Equipment.

With strong know‐how in the plastic moulding sector, Complastic Srl is developing a project to produce glasses and a face shields thanks to an injection moulding machine delivered by Negri Bossi to the company in record time. This project was funded by Invialia for the Cura Italia decree in order to deal with the emergency of Covid‐19.

The design of the two objects produced fully reflects the characteristics required by the EN166: 2004 standards, in addition, efforts have been made to give maximum transparency to the glasses also on the side, so that the wearer’s visual field is not diminished and with the purpose to decrease the mental tiredness caused by the use of the object for many consecutive hours.

In the work area for the project at the Complastic Srl company, the expected productivity at full capacity will be 2000 pieces per day for both glasses and face shield.

All this has been possible thanks to a symbiotic work, as well as with Negri Bossi also with ADM who made the mould of the glasses, with Moretto SpA who supplied the ancillaries of the machine (Polymer dehumidification plant, granulation plant that moulds thermoregulation), with the supplier of the raw material AT & Service srl (Pastorano ‐ CE) and that of the packaging, Paper Sun Sas.

The virus is raging and there seems to be no way out but in this situation that for the first time we all found ourselves living, reshaping our lives, it is our duty to strive to find a solution, to be an active part in the transformation that we are living and running towards “normality”.

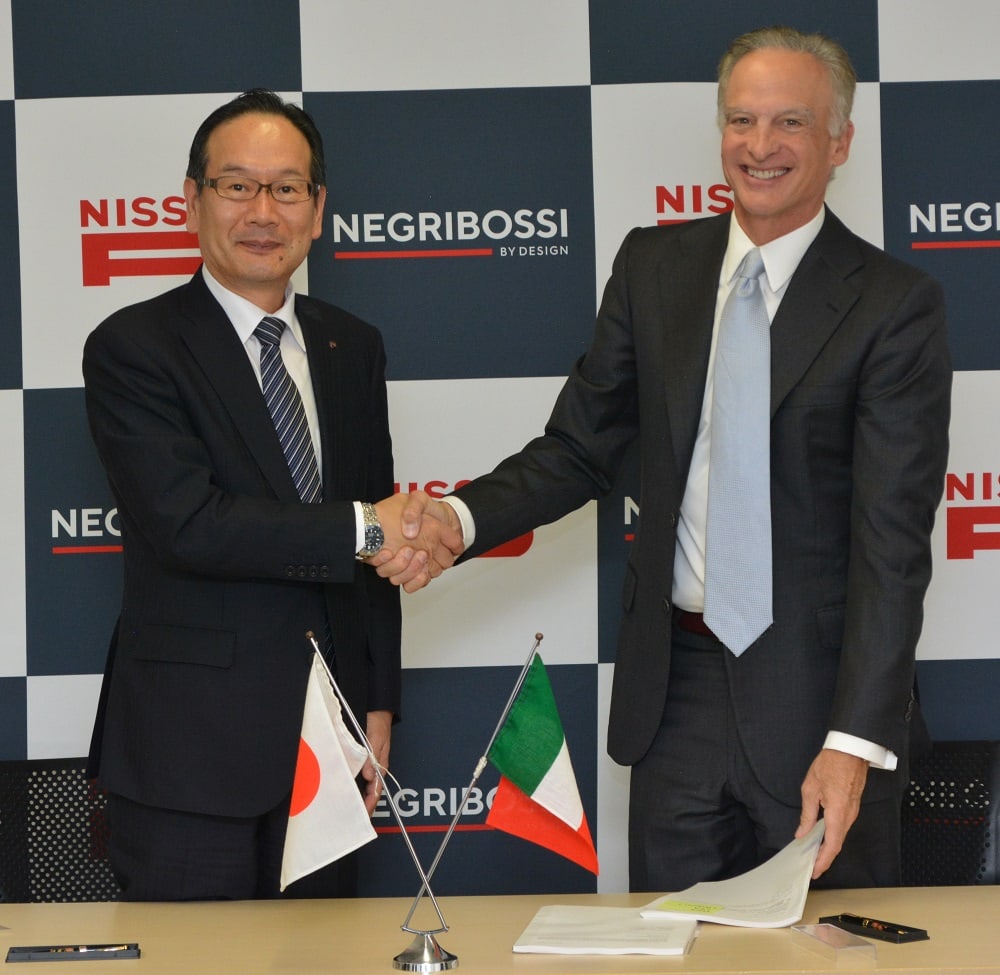

The virus is raging and there seems to be no way out but in this situation that for the first time we all found ourselves living, reshaping our lives, it is our duty to strive to find a solution, to be an active part in the transformation that we are living and running towards “normality”. On 21st November 2019, Kingsbury Corp. has signed to sell a majority stake of Negri Bossi S.p.A., an Italian company active in the manufacture and sale of injection moulding machines and robot equipment, to Nissei Plastic Industrial Co., Ltd.. The closing is expected in January 2020 and Kingsbury Corp. will maintain a minority stake in the Company.

On 21st November 2019, Kingsbury Corp. has signed to sell a majority stake of Negri Bossi S.p.A., an Italian company active in the manufacture and sale of injection moulding machines and robot equipment, to Nissei Plastic Industrial Co., Ltd.. The closing is expected in January 2020 and Kingsbury Corp. will maintain a minority stake in the Company.