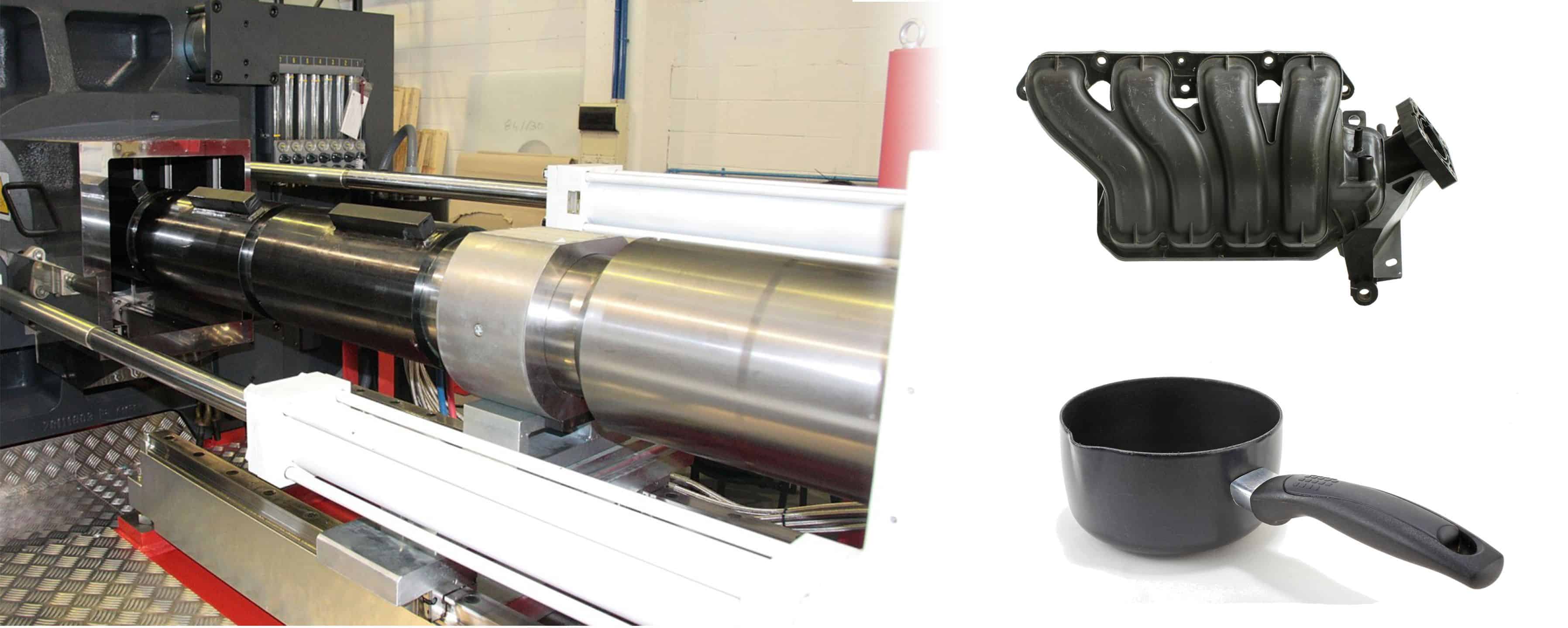

Thermoset Injection Moulding

Thermoset plastics are generally stronger than thermoplastic materials due to the three-dimensional network of bonds (crosslinking), and are also better suited to high-temperature applications. They have high mechanical strength and rigidity and are frequently used to replace metals, reducing the weight by as much as 75%. Thermoset materials are often used in vehicle engine compartments, oil pump and thermostat housings, water inlets & outlets and impellers. Brake linings and disk brake pads can also be manufactured in thermoset plastic.

Negri Bossi provides special applications for thermoset injection moulding. This solution includes all the equipment required for reliable and optimal production of high-quality moulded parts.

Specification

SPECIFICATION

Highlighted Features:

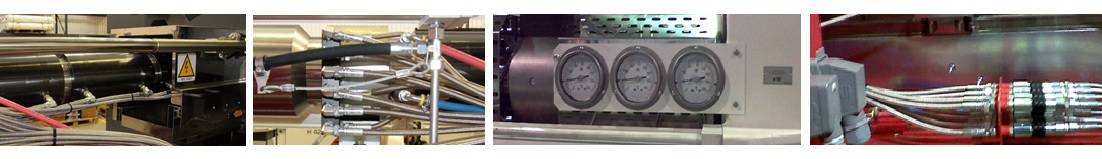

- Highly wear-resistant bi-metallic barrel

- Precise temperature control of plasticising barrel

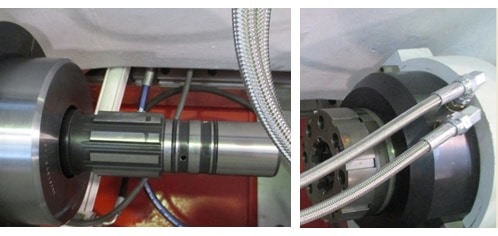

- Special screw geometries (compression free) with internal thermoregulation (80mm+ screws only) to ensure processing suited to the specific material

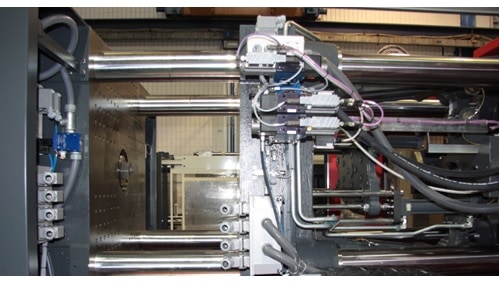

- Mould thermoregulation circuits

- Facility for venting and compression injection moulding

- Feed devices for Polyester materials

- Integrated robotic systems

Optional Features:

- Vacuum generator for the mould

- A program for de-gassing

- Process for tearing the sprue with the mould closed

Thermoregulated Screw and Barrel

THERMOREGULATED SCREW AND BARREL

- Available on screw diameters 80mm +

- Achieves optimal processing conditions and increased production levels