LIQUID SILICONE RUBBER INJECTION MOULDING TECHNOLOGY

For many years, Negri Bossi has maintained a strong involvement with the Liquid Silicone Rubber (LSR) injection moulding sector. In collaboration with the leading suppliers of material delivery systems and specialist mould makers, Negri Bossi has delivered turnkey systems for all types of LSR applications to many parts of the world.

Some examples of LSR applications include:

|

MEDICAL

|

AUTOMOTIVE

|

|

ELECTRICAL & APPLIANCE

|

SPORTS

|

|

GENERAL APPLICATIONS

|

MULTI-MATERIAL / MULTI-COMPONENT

|

LSR Machine

LIQUID SILICONE RUBBER MOULDING MACHINE

The Negri Bossi LSR solution features a standard injection moulding machine that is fitted with special LSR injection unit, LSR equipment options and LSR software.

1. The two component materials required for the LSR process are metered to the injection unit by a special delivery system. 2. The materials pass through a static mixing device… 3. … and into the machine barrel. 4. To prevent premature curing of the combined LSR materials, the barrel is fitted water jackets that allow closed loop thermal regulation. 5. The material is metered through an LSR tip assembly using a zero compression short L/D LSR screw, then during injection, through a pneumatically or hydraulically actuated, liquid-cooled, pin-type shut-off nozzle, and finally through a special LSR nozzle tip and into the mould.

The machine is also equipped with a range of features that are required for the LSR process and can also be fitted with several optional devices that may be useful to the process in specific circumstances.

Typical Features and Options:

- LSR Injection Unit (Special barrel and LSR screw with static seal)

- losed loop liquid barrel cooling

- Pin-type shut-off nozzle (Pneumatic or hydraulic actuation)

- LSR nozzle tip with static seal

- LSR tip assembly and non-return valve (Optional spring-lock positive shut-off design)

- Carriage decompression control

- Integral mold temperature control system

- Insulated platens

- LSR closed loop process software package for precise volumetric control

- Mould vacuum system (Vacuum pump, vacuum switch, interface, control software)

- Mould sweep software and sweep device interface

- Mould cold deck valve gate control system

- Air blow with pressure regulation

- Pre-dosing assembly with two component temperature controlled static mixer and purge valve

- LSR material delivery system

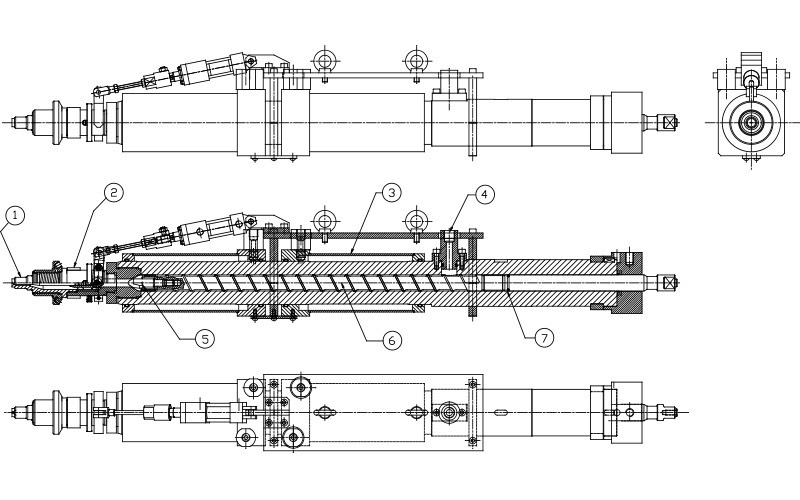

LSR Injection Unit

LIQUID SILICONE RUBBER INJECTION UNIT

The LSR process requires an injection unit designed specifically for the material and process. This unit should be appropriately sized for the application. Typically, this means that the component shot weight should be within 1 to 5 screw diameter stroke range. The main features are:

- LSR nozzle tip with static seal

- Pin-type, liquid cooled, shut-off nozzle (Pneumatic or hydraulically actuated)

- Closed loop liquid temperature control

- LSR zero compression 15:1 L/D screw with shank seal

- LSR non-return valve (Available with spring-lock positive shut-off)

- LSR dosing adapter

- Seal

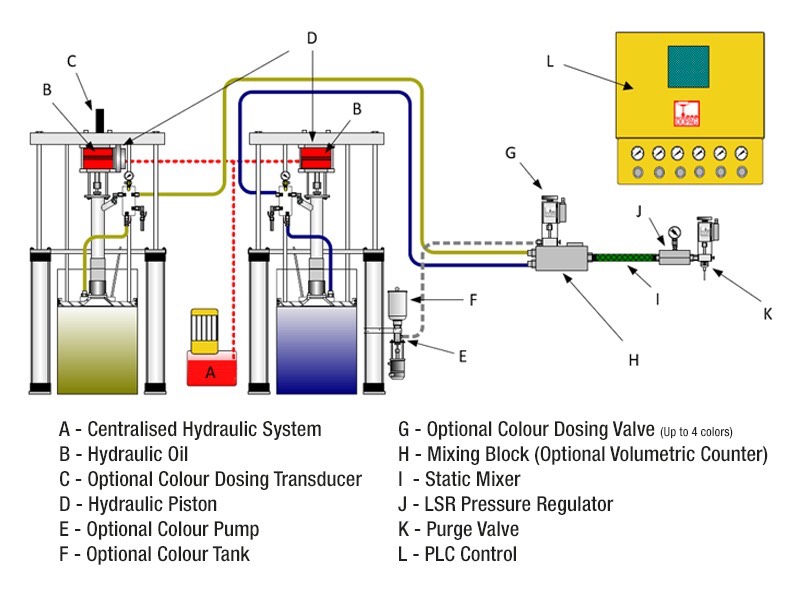

LSR Dosing Unit

LIQUID SILICONE RUBBER DOSING UNIT

The two components, once mixed in the desired ratios, are metered to the injection unit by a special delivery system. Negri Bossi partners with several suppliers of this specialist equipment to provide a turn-key LSR solution. Or, if the customer already has existing LSR delivery equipment, this can be easily interfaced to work with a suitably-equipped Negri Bossi LSR machine.

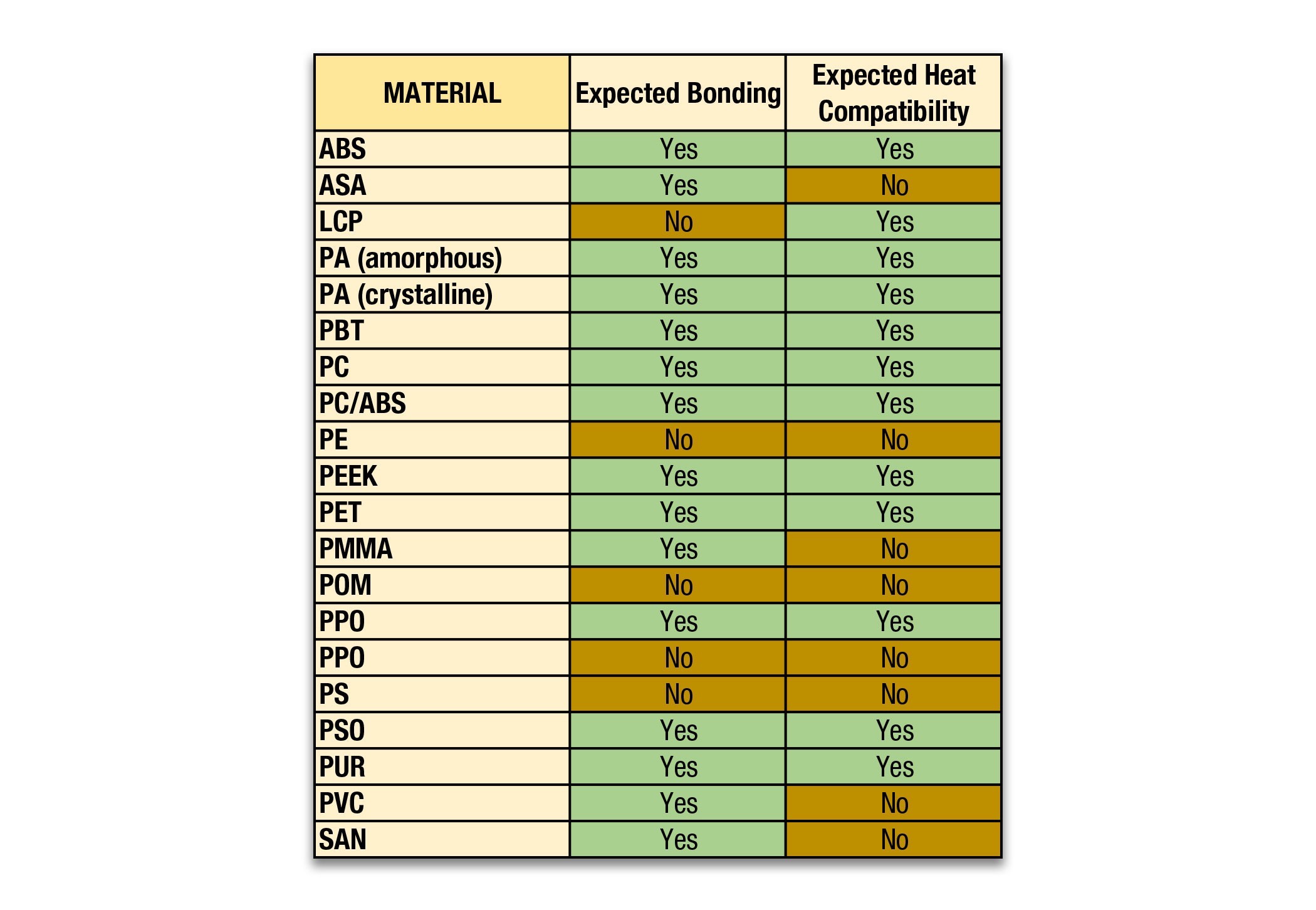

LSR Multi-Material Process

LIQUID SILICONE RUBBER MULTI-MATERIAL PROCESS

With a specially configured Negri Bossi MultiMat® LSR machine, and a specially-designed mould, it is possible to produce multi-material components that feature LSR as one of the elements. The LSR injection unit is usually on the main axis of the machine, but can also be arranged in a lateral or vertical position.

The table below shows the compatibility of LSR with a range of thermoplastic materials when used in combination, in a multi-material application.

Applicable Models

APPLICABLE MODELS

|

|

NOVA eT

|

|

NOVA sT

|