ALL ELECTRIC TECHNOLOGY

Precise • Efficient

Nova 5eT is the fifth generation of all-electric machines created for maximum precision and efficiency. The new clamping unit generates uniform contact pressure, and the injection unit materialises superior plasticisation. The TACT V controller provides excellent operability and the rigid bed structure supports stable high-cycle operation. Self-lubricating linear bearings on the moving platen and bush-less platen design ensure cleanliness in the moulding area, making the machine perfect for cleanroom environments. Centralised automatic grease lubrication is standard. Fully overlapping movements allow for reduced cycle times.

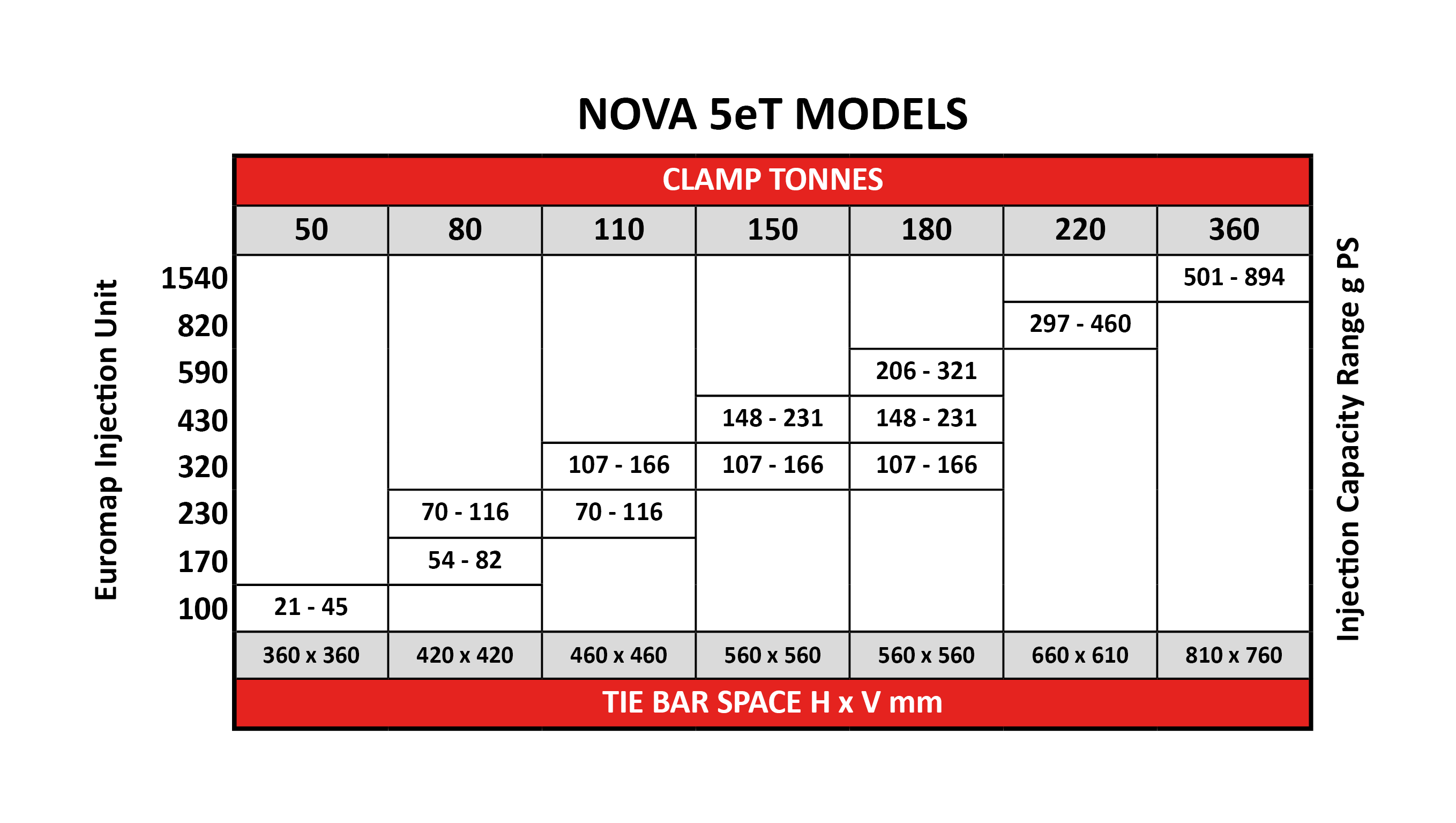

Specifications

Features

MAIN CHARACTERISTICS

- New “Flat Clamp Mechanism” for optimum contact pressure

- High Precision Metering Control with “Pre Pack”

- 3 methods of V-P changeover

- Low Particle Emission below Class 10,000

- Higher Platen Dynamic

- More Compact Footprint

FLAT CLAMP

- Reduced Toggle Bush Loading

- Prolonged Mould Life

- Reduced clamp force requirement

HIGH DYNAMIC TOGGLE

- Faster Open/Close Speeds

- High Sensitivity Mould Protection

- Automatic Force Adjustment

PRISMATIC LINEAR PLATEN GUIDES

- Optimal Platen Guidance

- Energy Efficiency

- Clean Environment

CLEAN OPERATION

- Reduced Particle Emission

- Centralised grease lubrication

- Cleanroom 10,000

TACT V

- User Friendly

- Touch control

- Connectivity

PRE-PACK

- Consistent Volume and Melt Density

- Stabilises Check Valve Response

- Auto adapt for batch inconsistencies

- Auto adapt for regrind

EG INJECTION UNITS

- Reduced Heat-Up Time

- Shorter Plasticising Times

- Improved Moulding Stability

COMPACT FOOTPRINT

- Upto 15% smaller footprint than previous series

- More machines per given area

- Higher factory output

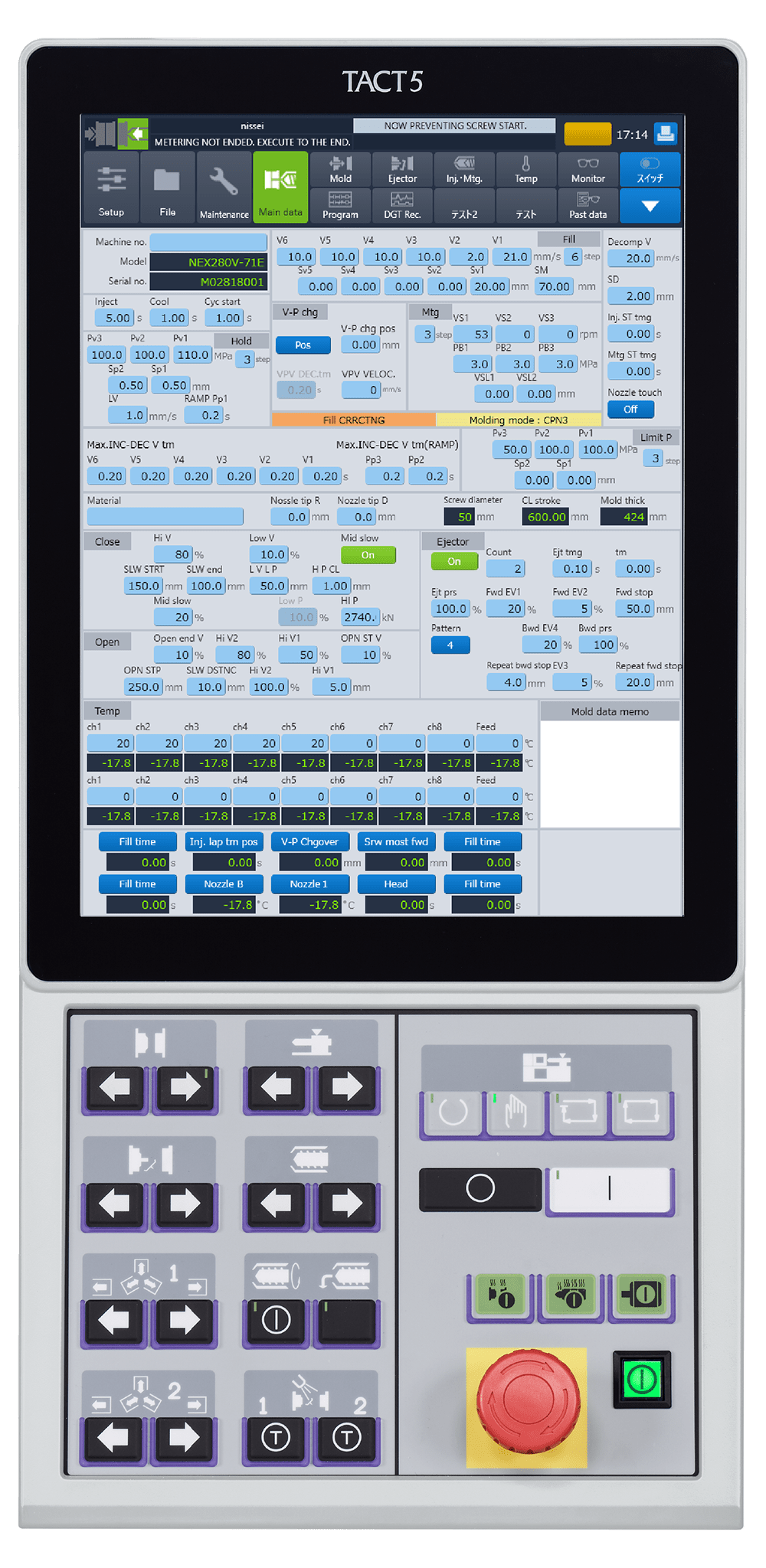

Controller

New controller for smart factory

- Improved controllability by adopting EtherCAT (high-speed field network).

- Support for EUROMAP77/83 is standardized by installing OPC-UA (communication standard between host systems) as standard.

- It is easy to connect with devices that are expected to play an active role in smart factories in the future, such as web cameras, QR scanners, and RFID (IC cards, etc.) devices.

Improved controllability with digital servo commands

- Digitalization of servo control eliminates disturbance components such as electrical noise, enabling more accurate control.

User-friendly screen design

- The screen design is easy to understand and use, not only for customers who are using Nissei but also for customers who are using it for the first time. The LCD display is 15 inches.

- A universal design is adopted to reduce the burden on the operator (colors with good visibility and large font size).

Improved screen operability

- It is possible to switch the upper and lower screens and scroll the history display and graph display.

Touch panel resistant to water and dust

- Even if the touch panel part is covered with water due to problems such as mould water pipe trouble, it will not break down easily.

OPTICAL

OPTICAL TECHNICAL

TECHNICAL