PVC Moulding Technology

Negri Bossi is one of the market leaders in supplying injection moulding machinery for processing PVC.

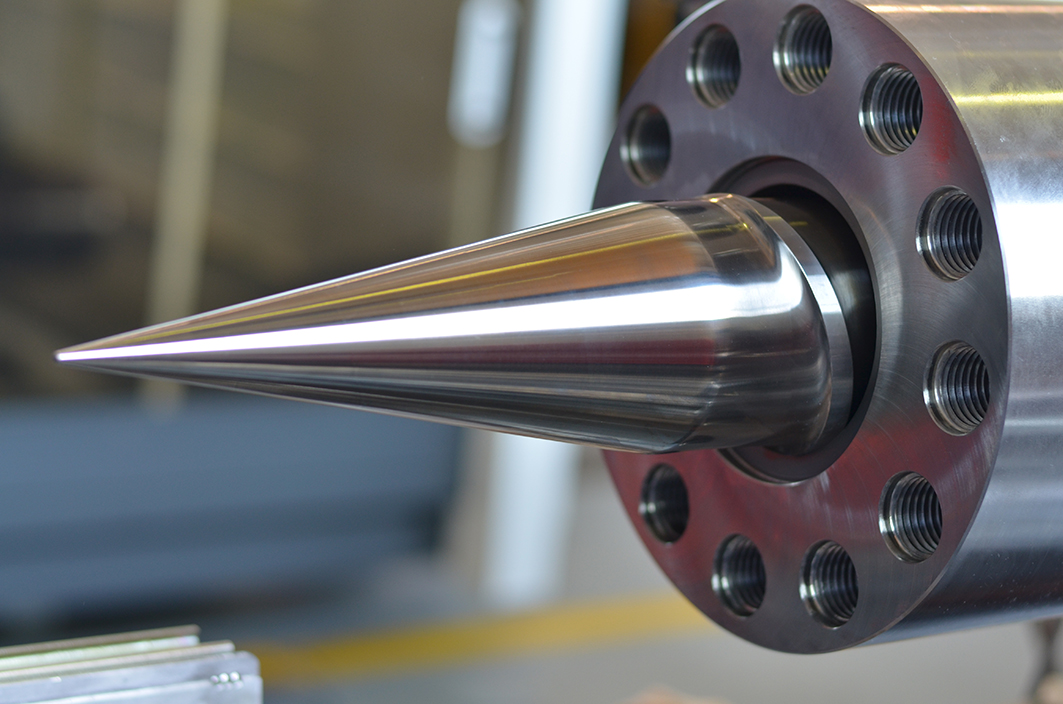

Even modern grades of Rigid PVC are less heat stable and have a smaller ‘processing window’ than most other thermoplastics. Flexible PVC can usually be processed on a standard injection moulding machine, often with a standard screw configuration, whilst most grades of Rigid PVC require a special machine application to ensure optimal processing conditions.

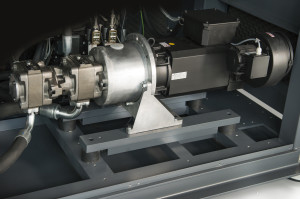

Negri Bossi’s PVC moulding machine technology has been developed to provide consistent and cost-effective production of visually and dimensionally perfect parts. Rather than offering a slightly modified standard machine, Negri Bossi have developed a more bespoke solution that provides the low shear, high torque, greater temperature regulation and resistance to chemical attack needed.

To demonstrate the degree of thought that goes into their PVC optimised machines, anti-corrosive components such as chrome-plated tie-bars are also specified, making sure that mechanical integrity and cosmetic appearance are preserved in the longer term.

Modularity

MODULARITY

Negri Bossi’s high level of modularity allows perfect matching of the injection unit to clamp size. This is most important for PVC, where residence times are particularly critical, but items such as drainage products require large tools with multiple moving cores.

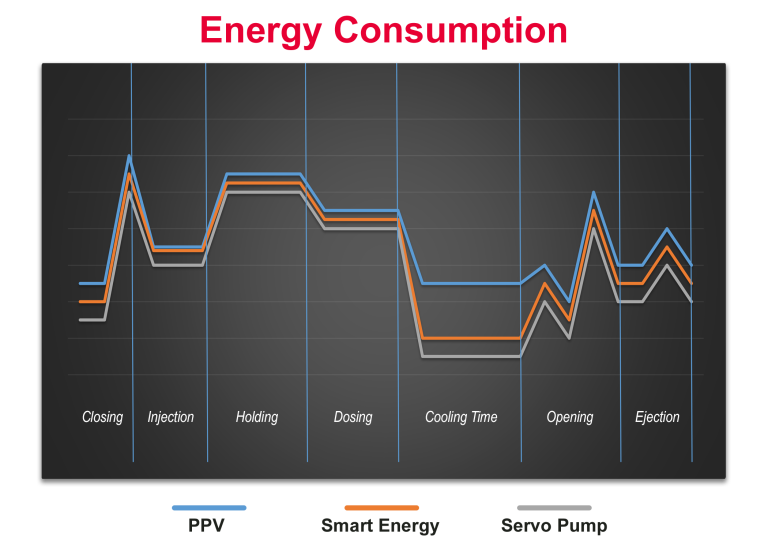

Energy Saving

ENERGY SAVING

Specification

SPECIFICATION

PVC ready models offer high torque hydraulic screw drive or optional electric screw drive on the ST range. These specifications provide the torque and screw speed stability required for optimum material processing.

Applicable Models

APPLICABLE MODELS

|

|

NOVA sT

|

|

NOVA ST

|

|

BIPOWER

|

|

VECTOR

|