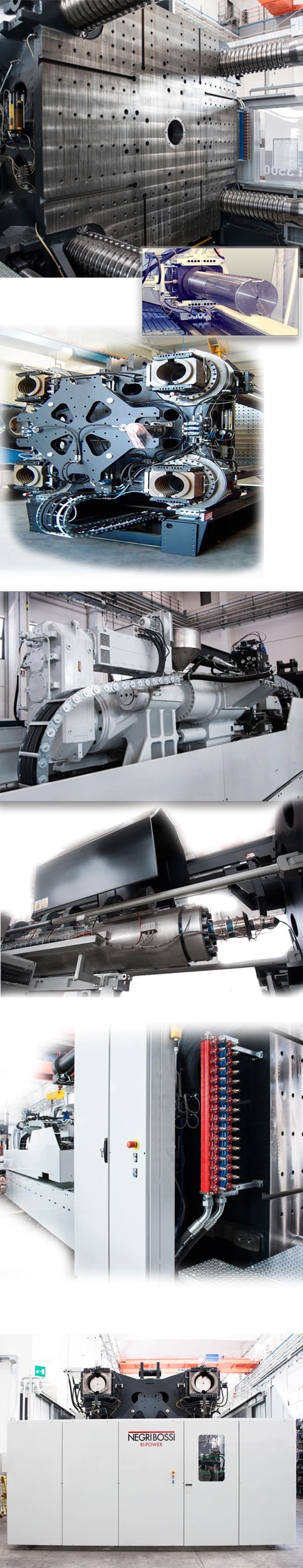

TWO PLATEN HYBRID TECHNOLOGY

Powerful • Efficient • Compact

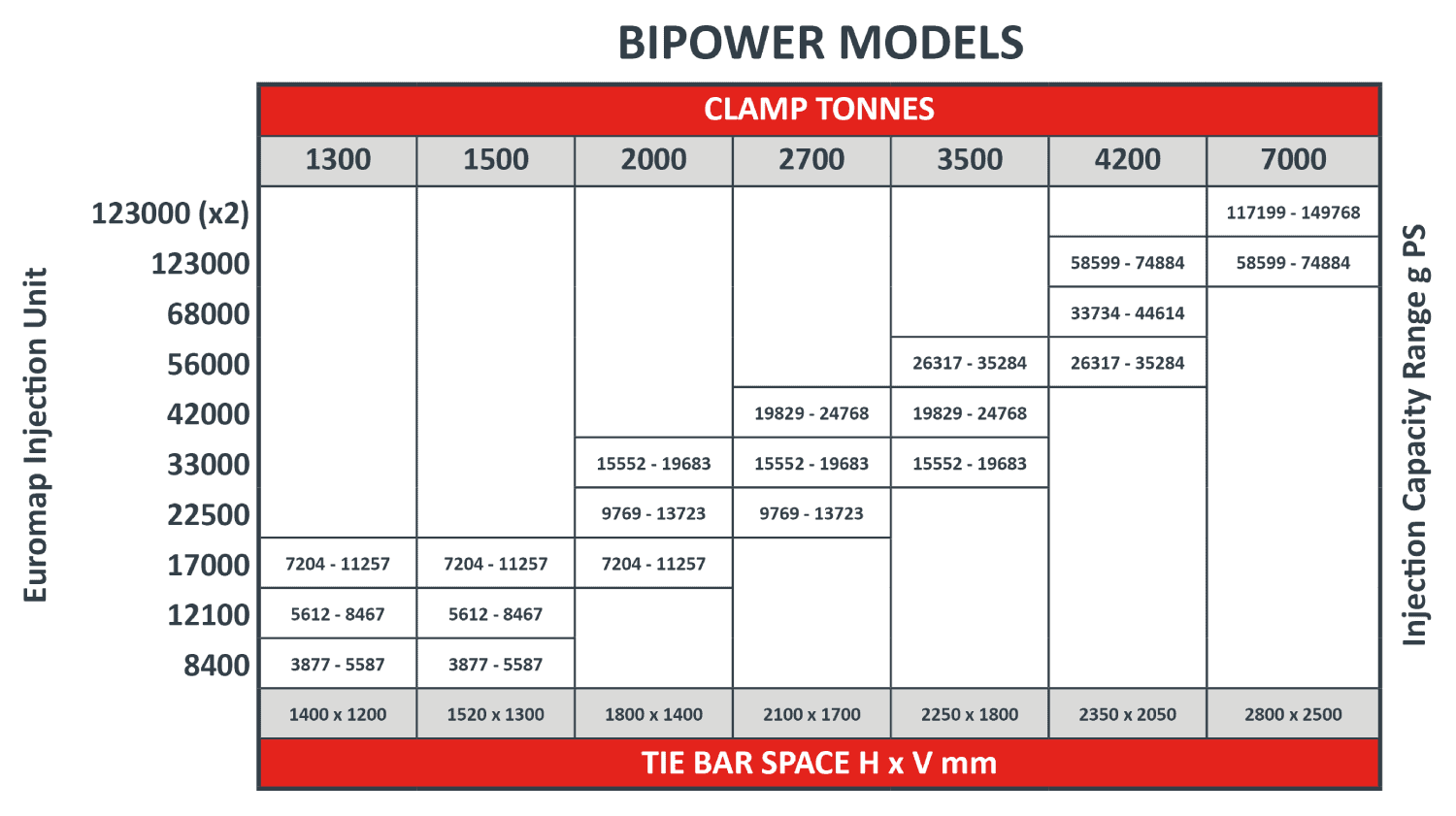

The BIPOWER Series are two platen clamp, hybrid power injection moulding machines available in 1300-, 1500-, 2000-, 2700-, 3500-, 4200- and 7000-tonne models. The injection unit features a reciprocating screw with electric screw rotation, with injection capacities (g PS) ranging from 3877 to 74884 (x1 injection unit 1300- to 7000-tonne models) and also 117199 to 149768 (x2 injection units on 7000-tonne model) across the line. Machines feature a highly modular design with low base for excellent accessibility. BIPOWER two platen injection moulding machines are equipped as standard with:

- Fully digital CanBus control

- Robust design for proven, reliable performance

- Clamping unit with generous tie bar spacing and clamping pistons on the moving platen for excellent reliability and faster dry cycle times

- Long ejector strokes

- Robust twin cylinder injection unit

- Electric screw drive for energy savings, and overlapping movements for faster cycle times

- Powerful, user-friendly C-TOUCH user interface with full range of control parameters

- AMICO wireless remote service access

Specifications

Features

CLAMPING UNIT

- Compact two platen clamping unit with high rigidity and minimal deflection

- Moving platen mounted ‘hydroblock’ tie bar locking system and clamping pistons

- Chrome plated tie bars

- Euromap or SPI platen configuration

- Moving platen with extended support shoes

- Moving platen linear and lateral guidance system

- Automatic mould thickness control

- Automatic central lubrication system by means of electric pump

- Three‐stage mould closing speed profile

- Three‐stage mould opening speed profile

- Moving platen pre‐feed

- Mould closing and opening stages governed through closed loop with proportional control valve

- Digital reading of moving platen position displayed on operator interface

- Mould thickness and clamping force self‐adjustment

- Digital reading of clamping force displayed on operator interface

- Two‐stage ejection speed profile

- Ejection force control

- Digital reading of ejector position displayed on operator interface

- Ejector proportional speed control, with overlapped movement at opening

- Repeated ejection with stroke and speed control

- Ejector return signal

INJECTION UNIT

- Twin cylinder injection unit

- Electric motor for screw controlled by vectorial inverter

- Closed loop motor speed control

- Injection unit sliding on linear bearings

- Swivelling injection unit for easy plasticising screw removal and cleaning

- Quick barrel change system

- Bimetallic barrel

- General purpose screw profile, suitable for most types of thermoplastic materials, special screw profiles on demand

- Injection unit driven by two cylinders to assure perfect nozzle centring

- Ceramic heater bands

- Alarm threshold for set temperature range

- Injection speed and pressure profiles

- Switch to holding pressure triggered by screw position, hydraulic pressure or time

- Digital reading of screw position displayed on operator interface

- Adjustable screw rotation speed profile

- Screw rotation delay

- Adjustable back‐pressure profile

- Digital reading of back‐pressure displayed on operator interface

- Decompression before and after screw recovery

- Intrusion moulding program

- Auto purge program

- Stainless steel hopper

HYDRAULIC SYSTEM

- Variable delivery pump with closed loop proportional flow and pressure control

- Digital reading of hydraulic circuit pressure displayed on operator interface

- Proportional control valve for moving platen movement

- Monitoring of oil level, temperature and oil filter efficiency

- Oil temperature control system

- Automatic cooling water shut-off valve

- Oil preheating program

- Off-line circuit for oil filtering and cooling

- Oil cooling with platen heat exchanger

- Tank window to ease cleaning

- Optical and electrical oil level gauge

ELECTRICAL SYSTEM

- Enclosure for electric components with IP55 protection

- Electric motors with thermal protection

- Interlocked main switch to prevent electrical cabinet from being opened when press is energised

- Overload cutouts for motor‐pump units and dosing motor

- Fuses and static relays for control of plasticising cylinder temperatures

- Vectorial inverter for screw rotation

- Fan for air circulation in electrical cabinet

- LED indicators on solenoid valves

- Fully labelled electrical circuits

- Conforms to Euromap or UL standards

COOLING CIRCUIT (Optional)

- Flow meter with adjustable independent circuits with water temperature and flow rate indication (One circuit is used for throat cooling with the remaining circuits available for mould cooling)

BASE

- Lowered base to optimise combined use of a robot

- Sound insulated motor‐pump compartment

- Anti-vibration mounting pad holes

- Lubricating oil recovery trough

SAFETY DEVICES

- Constructed in compliance with essential requirements of Machinery Directive 2006/42/CE and subsequent amendments

- All models CE certified by a European certification organisation

- Safety devices comply to European Standard EN 201 and ANSI/SPI B151.1-2007

- Safeguarding system at front of moulds with double interlocking device and hydraulic safety device

- Safeguarding system at rear of moulds with double interlocking device and shutdown of motor‐pump units

- Monitoring of correct operation of hydraulic and electric safety devices

- Interlocked nozzle purge guard

Controller

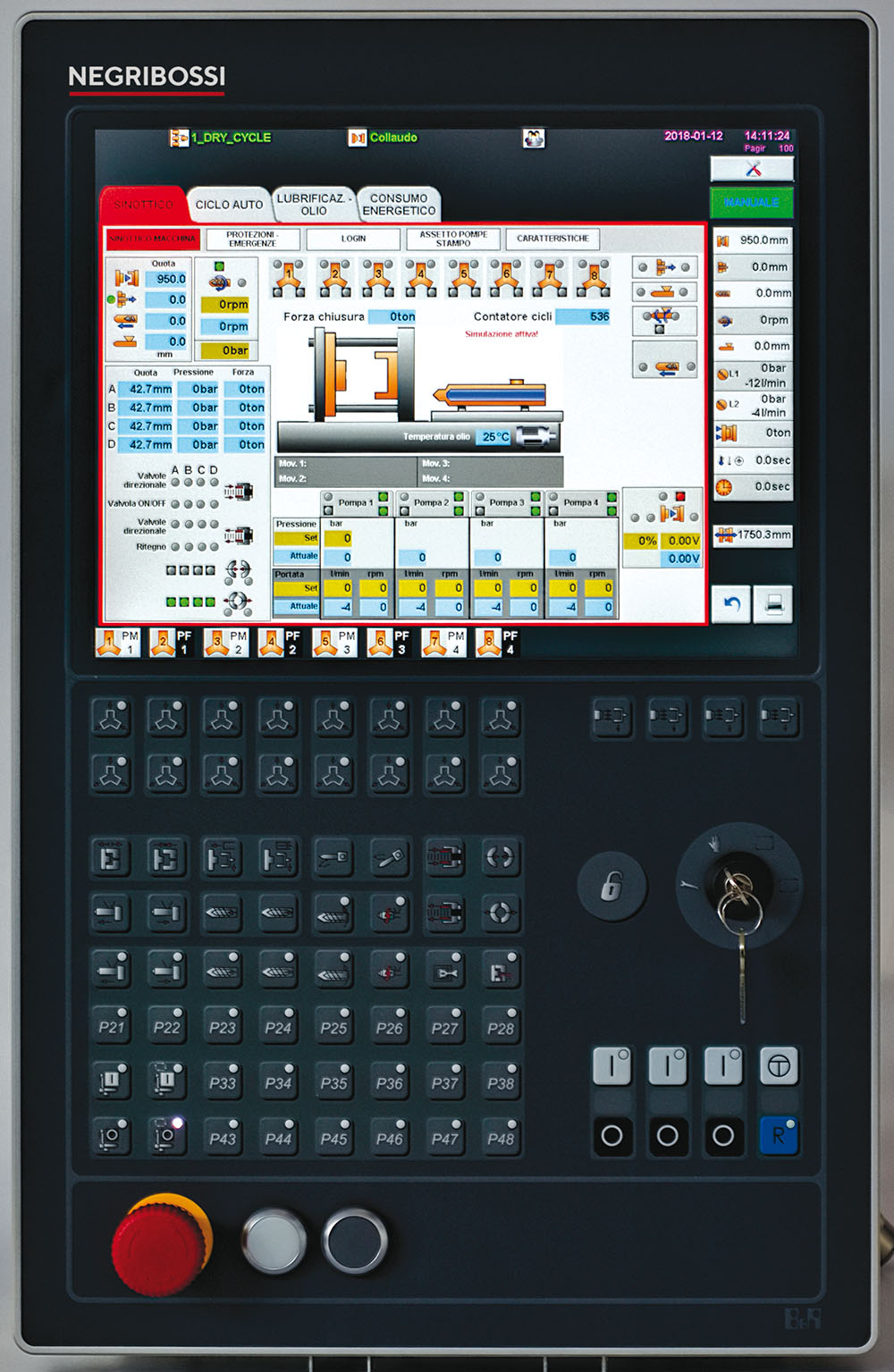

C-TOUCH CONTROLLER

- Single touch panel with analogic resistive technology

- Ergonomic, intuitive and highly configurable

- “Object Dropping” cycle programming. Easy, intuitive and fast

- High impact resistance

- Manages a wide range of temperatures and humidity

- High levels of precision using a touch screen stylus

- Fast Powerlink inter-process communication based on Ethernet technology

- Simple hardware configuration for complex special applications

- 15” XGA colour TFT display 1024 X 768 pixels

- Colour monitor

- IP52 protection

- Connections to machine with Harting connectors and IP65 protection

- Auto‐calibration program for all input and output channels

- Integral keyboard

- Dedicated display area for viewing of main process parameters

- Password and data input lock-out key

- Multi-language capability

- Hour counter

- Perpetual clock

- Page with press technical specifications

- Cycle times with sequence alarm page

- Three-stage mould closing with both speed and position adjustment

- Two pressures during mould closing with fully adjustable mould safety feature

- Mould pre‐feed

- Closed mould feedback signal

- Three-stage mould opening with both speed and position adjustment

- Closed loop control of mould opening position

- Cooling timer

- Lubrication cycles

- Clamping force readout

- Multi-stroke ejector

- Two ejection speed steps

- Partial return stroke during repeated ejection

- Adjustable ejector output and return pressure

- Free programming of ejector, air blow and core pulling

- Closed loop speed control for injection stage

- Closed loop pressure control for holding stage

- 10-Stage injection speed control with selectable number of stages

- Switching to holding pressure by time, hydraulic pressure or screw position

- 10-Stage holding pressure control with selectable number of stages

- Screw decompression before and after screw recovery

- Five-stage closed loop screw rotation speed control with selectable number of stages

- Five-stage closed loop back pressure control with selectable number of stages

- Self‐adjusting shot size control system

- Speed and pressure for control for carriage movements

- Program to automatically calculate the required shot size according to the material type and part weight

- Barrel temperature PID control

- Self-tuning program for cylinder temperature control

- Weekly clock to set the time the cylinder turns on and shuts off and three additional outlets

- Quality control (20 parameters) with direct display of the last 200 cycles in graphic form

- Production control

- High resolution graphics for real pressures, screw speed, screw position and cavity pressure

- Sample curve for each data item can be saved in a graph

- Zoom

- Set points displayed

- Fill Index

- Memo page

- Can work with graphic or other types of printers

- Page showing current faults with description and instructions on how to reset

- Real machine status (analog inputs and outputs) at time fault occurred

- Events history with possibility to view last 200 events regarding faults, shutdowns, and changes made to parameters

- Diagnostics page for digital inputs, analog inputs and analog outputs

- Self‐adjusting functions for all analog inputs and outputs

- Internal archive for more than 500 moulds

- USB Interface

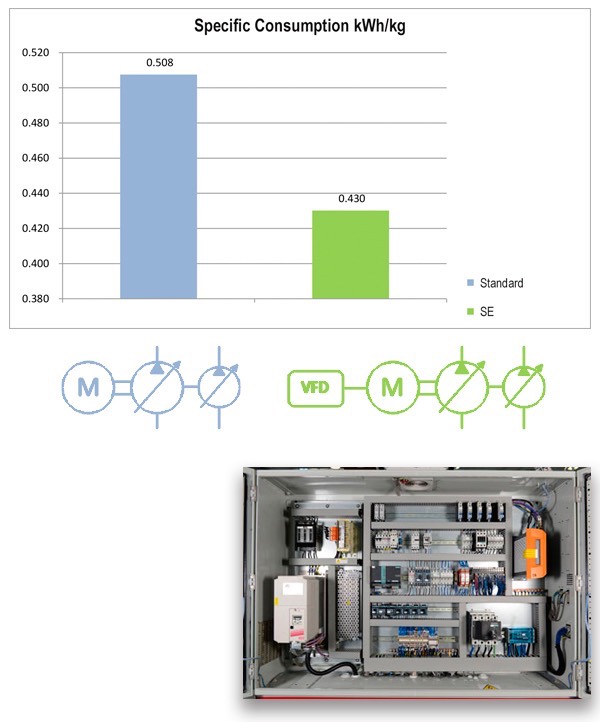

Smart Energy

SMART ENERGY OPTION

The Smart Energy option incorporates an electric motor that runs at variable RPM, with closed loop control via an inverter drive and in parallel with the variable delivery of the pump. In this situation, the controller optimises the motor RPM with the displacement of the pump in order to deliver the required volume of oil in the most efficient combination. As well as providing improved efficiencies in all situations due to optimum motor/pump combination, remarkable savings are achieved during the idle parts of the cycle, notably during hold time and cooling phase. During these phases, the electric motor can drop to 600 RPM therefore achieving a huge reduction in power consumption. Benefits of the Smart Energy option include:

- Energy consumption as low as all-electric technology (depending on cycle breakdown)

- Noise levels comparable to all-electric machines

- Superior shot weight precision due to faster response time of change over to hold on pressure

- Dramatically increased life of the hydraulic oil

- Reduced chiller running costs

- Increased hydraulic component life

Options

AVAILABLE MACHINE OPTIONS FOR BIPOWER

- Core Pull MP/FP

- Air Blast MP/FP

- Proportional Valve for Hydraulic Ejection

- E17 Interface

- E12 Adapter Plug

- E67 Robot Interface

- Integrated Robot Interface

- Special Screw (Wear Resistant, Corrosion Resistant, Mixing, Barrier, Low Compression, etc.)

- Special Barrel (Corrosion Resistant, High Wear Resistant)

- Barrel Liner

- Special Tip Design

- Extended Nozzle Body

- Additional Nozzle Zone

- Mould Valve Gate Hydraulic

- Mould Valve Gate Pneumatic

- Hydraulic Shut-Off Nozzle – Bolt

- Integrated Hot Runner

- Mould Pressure Transducer Interface

- Gas Injection Interface

- Data Logging Interface

- RJG Process Monitoring Interface

- Special Paint

- Additional Flowmeters

- Feed Throat Cooling

- PVC Kit

- FMC®

- Power Outlet(s)

- Colour Feed Signal

- Photocell with Muting

- Injection Accumulator

- Magnetic Platens

- Hydraulic Mould Clamps

- Rotary Table

- AMICO System Services

Markets

BIPOWER END MARKET APPLICATIONS

- General Large Size Parts

- Automotive

- Construction

- Industrial

- Appliance

- Household

- Aerospace

- Technical Moulding

- Containers

ENVIRONMENTAL

ENVIRONMENTAL