SERVO POWERED TOGGLE TECHNOLOGY

Versatile • Productive • Efficient

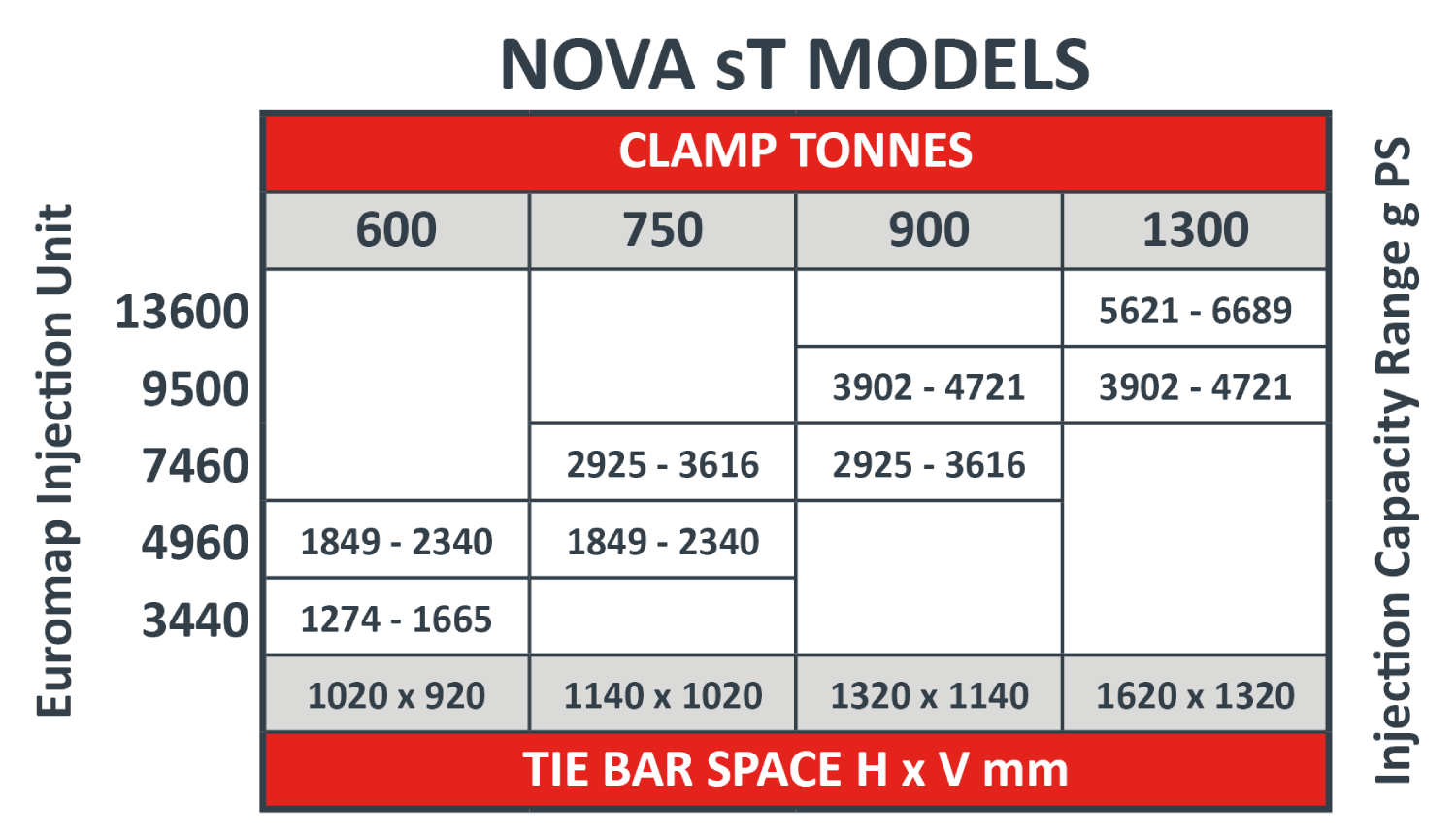

The new design and upgraded clamp and injection unit of the Negri Bossi Nova sT range combines versatility, compactness and control.

Energy efficiency was at the forefront of the design consideration incorporating the very latest servo-pump technology, purpose built for injection moulding applications.

The NOVA range is equipped with Motus, the first ‘True’ Multi touch Controller:

- Innovative gesture navigation system incorporating swipe, scroll & zoom functions

- Virtual object for axis movement based on gesture orientation (Patent Pending)

- Modern, slim design with smartphone familiarity

- Customisable interface to personalize screen and functions

- Sequencer to create special cycles

- Quick search function for parameter editing, graphical editing and analysis

Key features of the NOVA sT servo hydraulic injection moulding machine include:

- X-Design toggle system – revolutionary compact design

- Class leading tie- bar spacing

- Platen stroke increased by up to 16% on previous models

- Pressure on material – increased by over 15%

- Injection speed – increased by over 25% with regeneration

- Amico 4.0 preparation

CONTRACT MOULDING

CONTRACT MOULDING