NEGRI BOSSI PLASTIC MOULDING ROBOTS & AUTOMATION

Negri Bossi offers Cartesian robots for customers who require a turnkey moulding and part removal solution. Part removal robots are available in both E67 non-integrated and fully integrated configurations.

E67 Non-Integrated Configuration

-

Robot with an independent controller unit

Available on Robot Models

- S6, S8-S, S8-L, S9-S and S9-L advanced non-telescoping robots

- S9T-S, S9T-L, S10-S, S10-L, S20-S, 251G, 301G, 401G and S50 advanced telescoping robots

Integrated Configuration

Integrated Configuration

- Robot with control achieved through the moulding machine controller

- Includes special integrated-control pendant

Available on Robot Models

- S6, S8-S, S8-L, S9-S and S9-L advanced non-telescoping robots

- S9T-S, S9T-L, S10-S, S10-L, S20-S, 251G, 301G, 401G and S50 advanced telescoping robots

NEGRI BOSSI SOLVES AUTOMATION CHALLENGES

Smaller size robots are available in either non-telescoping or telescoping design, with the medium and larger units available only as telescoping models.

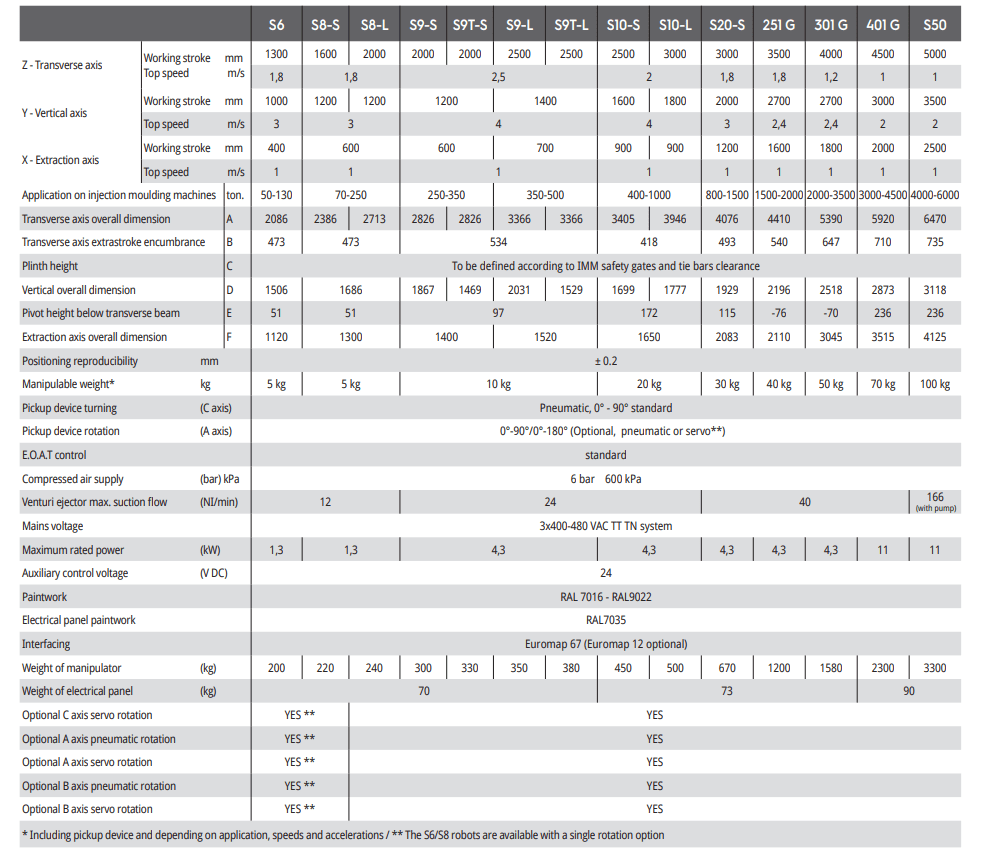

Specifications

Non-Telescoping Robots

S6, S8-S, S8-L, S9-S and S9-L MODELS

- Advanced non-telescoping Cartesian robots

- Generous I/O expansion capabilities

- Peripheral upstream and downstream device control

- Available in E67 non-integrated configuration with SCP2 Controller pendant

- Also available in fully integrated versions with integrated-control pendant

STANDARD EQUIPMENT

- Steel traverse beam

- Simultaneous movement of all axes

- Strip stroke can be pushed back with the ejectors (X-Free Function)

- Pneumatic 90-degree C-Axis

- Single vacuum circuit

- Single pneumatic circuit

OPTIONAL EQUIPMENT

- Spare I/O’s

- Vacuum circuits with sensing

- Vacuum pump

- Additional pneumatic circuit with single solenoid valve

- Additional pneumatic circuit with double solenoid valve

- An additional circuit for blow function

- Energy-saving vacuum generator

- A-Axis pneumatic rotation

- B-Axis pneumatic rotation

- A-Axis servo rotation

- B-Axis servo rotation

- C-Axis servo wrist

- Traverse beam extension

- End of arm tooling (EOAT)

- Integrated conveyors

- Category 2 and 3 safety enclosures

- C-Axis wrist electrical connector

- Quick changer tool (robot side)

- Quick changer tool (gripper side)

- Dual operator pendants

- Wireless capability (Wi-Fi)

- Custom paint colours

SCP2 CONTROLLER PENDANT (For use with E67 non-integrated configurations)

- Large 18 cm (7 inch) colour touch screen display for easy operation, programming and diagnostics including ergonomic handle and anti-panic button

- Safety switch

- Simple, quick auto-learning of positions by means of personalised dedicated screens

- Adjustable vacuum level control for monitoring of part presence on end-of-arm-tooling (EOAT)

- Modification of working positions (with safety ensured), times and counters during robot automatic cycle

- Parallel programs for management of auxiliary tooling without affecting the robot’s operating phases

- Auxiliary functions available: pneumatic axes, vacuum, grippers, belts, peripherals

- Advanced programming functions for complex cycle creation

- Control of up to six servo-motor axes

- Extraction cycle with a function that reduces the applied torque if robot movement cannot be synchronised with that of the mould extractors

- S-Shaped acceleration ramps to reduce vibration and protect mechanical components

- Dynamic advance functions for high-speed cycles

- Expandable I/O’s

- Palletising macros for simple configuration of the sequence and stack configuration

- Automatic work cycle selection by means of a code received from the gripper or injection moulding machine

- Multi-level password access

- Multilingual support, including two with immediate selection

- Alarm log for diagnostics and monitoring of any malfunctions

- USB port for backup of robot programs and parameters on memory sticks

- Ethernet connection for remote assistance and connection to the company network

- System parameters configurable from the control to activate the management of devices and functions

- Offline programming

- Control of the moulding machine’s core pulls, conveyor belt and peripherals

- Eight working areas to establish permitted robot paths

- Standard palletising program

- Diagnostics are shown on the pendant screen

- Internal storage for 100 main programs with 100 sub-programs

- USB drive

- Input and Output modules are expandable up to 961/960

- Simultaneous execution of up to 20 program lines

- Customisable I/O and variables names

- Eight user-definable safe working areas

- Monitoring of system and maintenance conditions

- Alarm history can be viewed and downloaded via the USB port

- Control is Network Ready (no additional software required)

Telescoping Robots

S9T-S, S9T-L, S10-S, S10-L, S20-S, 251G, 301G, 401G and S50 MODELS

- Advanced telescoping Cartesian robots

- Generous I/O expansion capabilities

- Peripheral upstream and downstream device control

- Available in E67 non-integrated configuration with SCP2 Controller pendant

- Also available in fully integrated versions with integrated-control pendant

STANDARD EQUIPMENT

- Steel traverse beam

- Simultaneous movement of all axes

- Strip stroke can be pushed back with the ejectors (X-Free Function)

- Pneumatic 90-degree C-Axis

- Single vacuum circuit

- Single pneumatic circuit

OPTIONAL EQUIPMENT

- Spare I/O’s

- Vacuum circuits with sensing

- Vacuum pump

- Additional pneumatic circuit with single solenoid valve

- Additional pneumatic circuit with double solenoid valve

- Additional circuit for blow function

- Energy-saving vacuum generator

- A-Axis pneumatic rotation

- B-Axis pneumatic rotation

- A-Axis servo rotation

- B-Axis servo rotation

- C-Axis servo wrist

- Traverse beam extension

- End of arm tooling (EOAT)

- Integrated conveyors

- Category 2 and 3 safety enclosures

- C-Axis wrist electrical connector

- Quick changer tool (robot side)

- Quick changer tool (gripper side)

- Dual operator pendants

- Wireless capability (Wi-Fi)

- Custom paint colours

SCP2 CONTROLLER PENDANT (For use with E67 non-integrated configurations)

- Large 18 cm (7 inch) colour touch screen display for easy operation, programming and diagnostics including ergonomic handle and anti-panic button

- Safety switch

- Simple, quick auto-learning of positions by means of personalised dedicated screens

- Adjustable vacuum level control for monitoring of part presence on end-of-arm-tooling (EOAT)

- Modification of working positions (with safety ensured), times and counters during robot automatic cycle

- Parallel programs for management of auxiliary tooling without affecting the robot’s operating phases

- Auxiliary functions available: pneumatic axes, vacuum, grippers, belts, peripherals

- Advanced programming functions for complex cycle creation

- Control of up to six servo-motor axes

- Extraction cycle with a function that reduces the applied torque if robot movement cannot be synchronised with that of the mould extractors

- S-Shaped acceleration ramps to reduce vibration and protect mechanical components

- Dynamic advance functions for high-speed cycles

- Expandable I/O’s

- Palletizing macros for simple configuration of the sequence and stack configuration

- Automatic work cycle selection by means of a code received from the gripper or injection moulding machine

- Multi-level password access

- Multilingual support, including two with immediate selection

- Alarm log for diagnostics and monitoring of any malfunctions

- USB port for backup of robot programs and parameters on memory sticks

- Ethernet connection for remote assistance and connection to the company network

- System parameters configurable from the control to activate the management of devices and functions

- Offline programming

- Control of the moulding machine’s core pulls, conveyor belt and peripherals

- Eight working areas to establish permitted robot paths

- Standard palletizing program

- Diagnostics are shown on the pendant screen

- Internal storage for 100 main programs with 100 sub-programs

- USB drive

- Input and Output modules are expandable up to 961/960

- Simultaneous execution of up to 20 program lines

- Customisable I/O and variables names

- Eight user-definable safe working areas

- Monitoring of system and maintenance conditions

- Alarm history can be viewed and downloaded via the USB port

- Control is Network Ready (no additional software required)

SYTRAMA PART REMOVAL ROBOTS

The Negri Bossi product portfolio also includes SYTRAMA brand part removal robots for a range of moulding applications. These robots can be configured to fit any existing brand of machine, allowing the Negri Bossi customer to enjoy commonality of spare parts and controller technology. Learn more about SYTRAMA robots here.

Integrated Configuration

Integrated Configuration