Arlington Thermal Management (UK division), part of the Arlington Automotive group, is a Tier 1 strategic supplier to major automotive OEMs including Ford, Jaguar Land Rover, BMW, Daimler and Renault Nissan.

Whether it’s for automotive or non-automotive applications, the company offers a full system service for cooling flow controls and powertrain thermo-management.

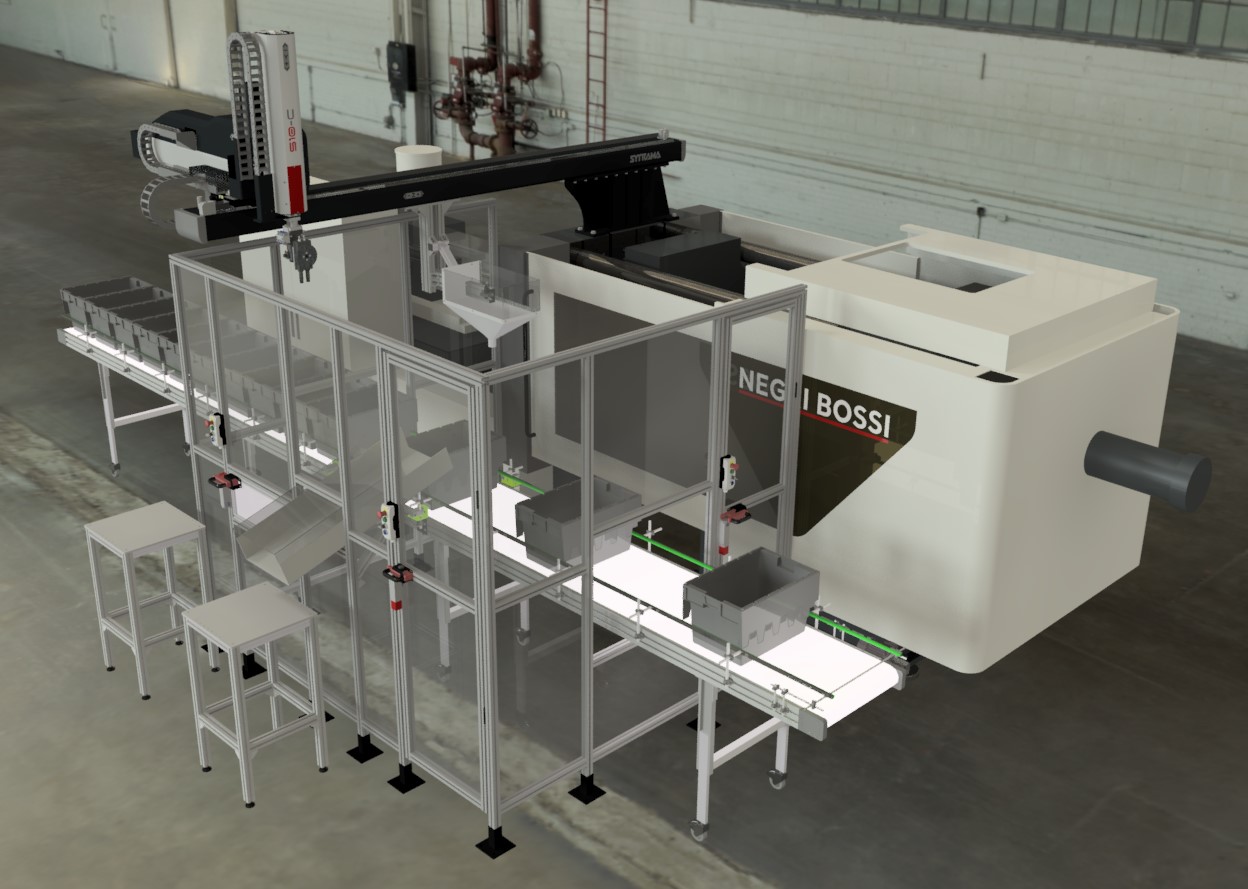

The Negri Bossi team were tasked to work with the Arlington team to create two identical machine and robot cells to manage the continual output from a new suite of extremely complex multi-cavity moulds. The tools would be producing high glass content, nylon thermostat bodies and covers, some body moulds requiring there to be eight independent hydraulic core pull circuits on each of the two 500 tonne machines.

All the moulds in the suite had to be interchangeable between the two cells, quick-change robot heads with binary-coded gripper connections were specified to prevent any error in gripper selection.

Automatically ensuring only good parts reached the post moulding assembly shop was a fundamental requirement for the company, as this would eliminate wasted resources further down the production line. Communication between the IMM and the automation system was therefore key, allowing each cell to fully utilise the sophisticated standard quality monitoring system within the latest CANBIO ST machine’s Tactus control.

Operations Manager, Paul Adams commented:

“Our history with Negri Bossi machines had proven to us we could rely on very precise shot to shot repeatability in the long term. We have machines dating back to 1995 that still surpass our demands for an accurate and stable moulding process. It was imperative that the new lines had this inherent repeatability, but could also warn us of any undesirable trends in the process, for example, material and mould heating/cooling instability.”

“We wanted to continue to work with a company that could supply a complete solution from their own product range, rather than having to piece together a system that wasn’t designed to work in harmony. As Negri Bossi have their own specialised automation company, namely Sytrama, as well as a UK based project manager, they are well suited to this task.”

Improved labour utilisation was another joint target. Operator intervention to the cells for parts distribution to the assembly lines were to be no more frequent than once every 2 hours. This was achieved with a custom-built conveyor system designed to accommodate the company standard, in house parts containers. Active box position monitoring and operator attraction by audible and visual indicators were incorporated in the line.

To allow quality control patrol inspectors to take samples from the enclosed system, quality staff can simply press a request button, and the robot will divert components to a quality station. These components are then excluded from the sample count within the normal production control. The same applies to any parts produced outside the CANBIO’s quality monitoring system, the robot depositing ‘suspect’ components on a quarantine table.

The system is also programmed to automatically quarantine a selectable number of cycles at start-up and after any system interruption. This allows process stability to be achieved before components enter the system. As before, the correct box counts are still maintained.

Paul Adams commented:

“The two production cells are now fully operational and have achieved the stringent targets set during our initial consultations with Negri Bossi. The net result is a much higher level of production autonomy, with a significant reduction of non-conforming product entering our ‘downstream’ manufacturing systems.