Foam Microcellular Moulding (FMC) Process

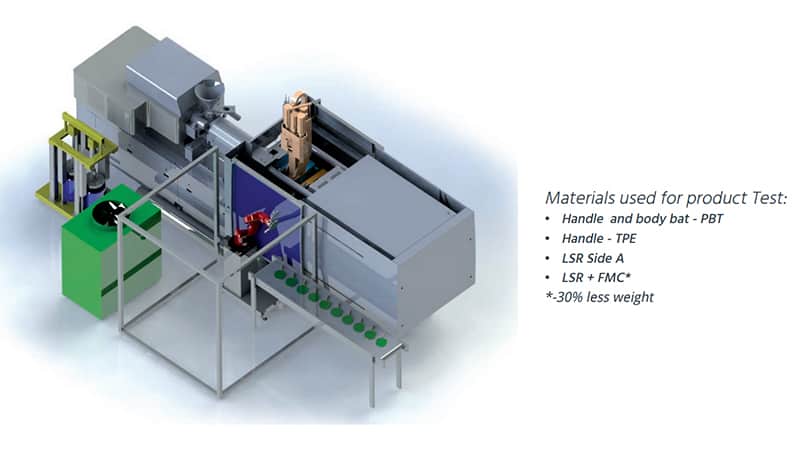

More and more plastic components need mechanic resistance and weight reduction. Using Negri Bossi’s experience in gas injection, we have developed a solution which reduces the component weight, increases the mechanical properties and enhances the chemical quality of the material.

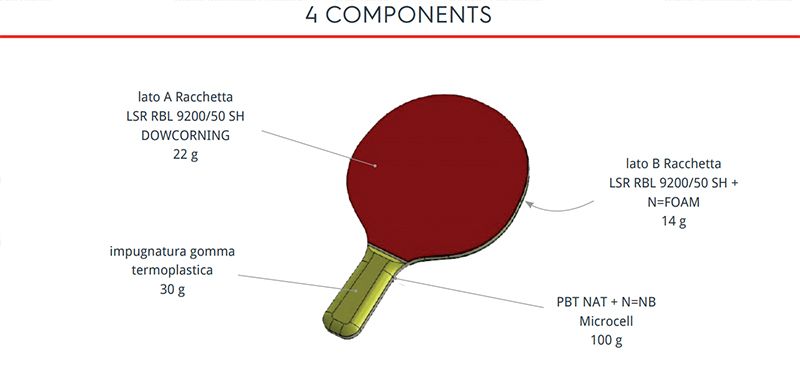

This application produces moulded material in a microcellular form and is available for both thermoplastics and liquid silicon rubber (LSR).

FMC Idea

Simplicity

Simplicity is the key word. The primary goal was to find a solution where there were no major changes to the base components of the machine whilst simultaneously obtaining a microcellular result via a reliable and repeatable process, configurable to the product’s needs.

Another challenge was to apply this process to all Negri Bossi’s existing machines, not only the current series but to those already installed at our customers.

Advantages

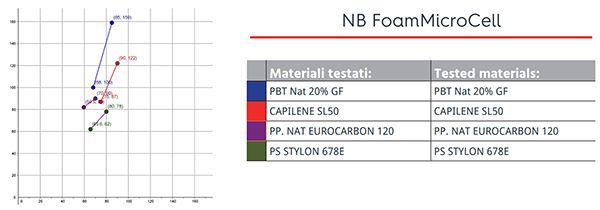

- Weight Reduction: less material used

- Viscosity melt reduction during injection phase

- Clamping force reduction for the piece production

- Cycle time reduction

- Improved dimensional moulding control

What we can achieve with FMC

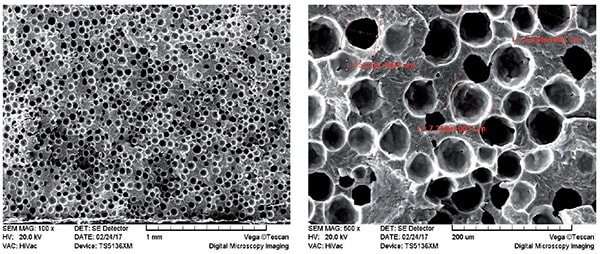

Scanning electron microscope (PA66)

FoamMicroCell Equipment

FoamMicroCell Equipment

FMC® Negri Bossi System includes:

- Nitrogen Bottles

- Proportional control valve

- Special profile Negri Bossi screw

- Pneumatic / hydraulic nozzle

- Interface Software

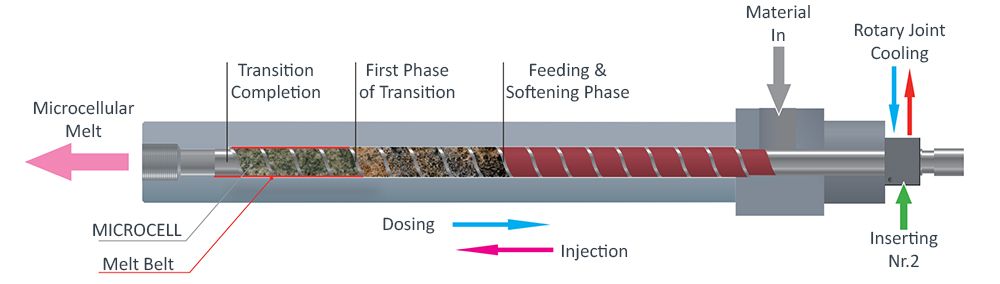

How FMC Works

How FMC Works

Applicable Models

APPLICABLE MODELS

|

NOVA sT

|

|

NOVA sT

|

|

BIPOWER

|

|

NOVA eT

|

|

VECTOR

|