NEGRI BOSSI INJECTION MOLDING MACHINES

Negri Bossi offers a wide range of injection molding machines to the global marketplace, engineered for maximum reliability, performance and durability. Our product portfolio features a comprehensive range of injection molding machines that are designed to meet the various needs of molders while keeping a focus on energy consumption, footprint, accessibility, and savings. We offer both toggle and two-platen models with hydraulic, hybrid and all-electric power configurations ranging from 70 to 7000 tonnes of clamp force.

TOGGLE INJECTION MOLDING MACHINES

|

NOVA 5eT

|

|

NOVA sT (180-500 tonnes)

|

|

NOVA sT

|

|

VECTOR sT

|

|

|

|

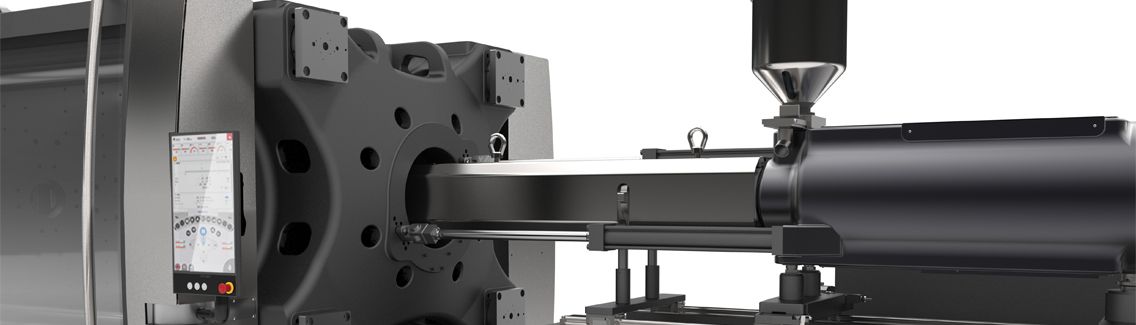

TWO-PLATEN INJECTION MOLDING MACHINES |

|

|

BIPOWER

|

SPECIAL MACHINES

Negri Bossi offers a variety of injection molding machines that are custom-engineered and equipped to handle special molding applications. Find out about Negri Bossi special application machines here, or browse through each of our injection molding machine products above.