MORE MATERIALS & MULTIPLE COLOURS WITH A SINGLE MACHINE

Versatile • Modular

Thanks to the modularity of the Negri Bossi machines, the MULTIMAT series is born. To satisfy an increasingly “technological” and “colourful” market, the Multimat series has been created starting from the simplicity and functionality of the new product lines Bossi.

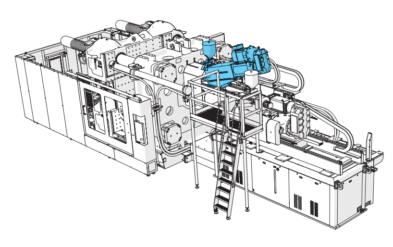

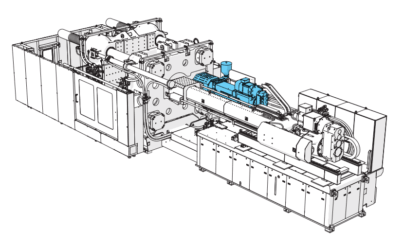

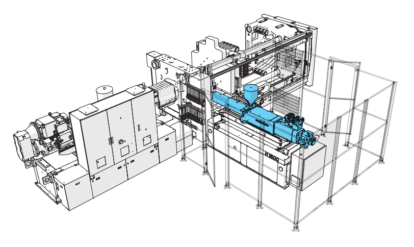

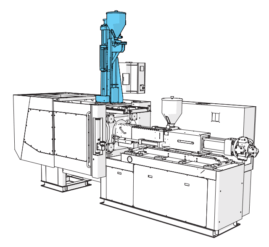

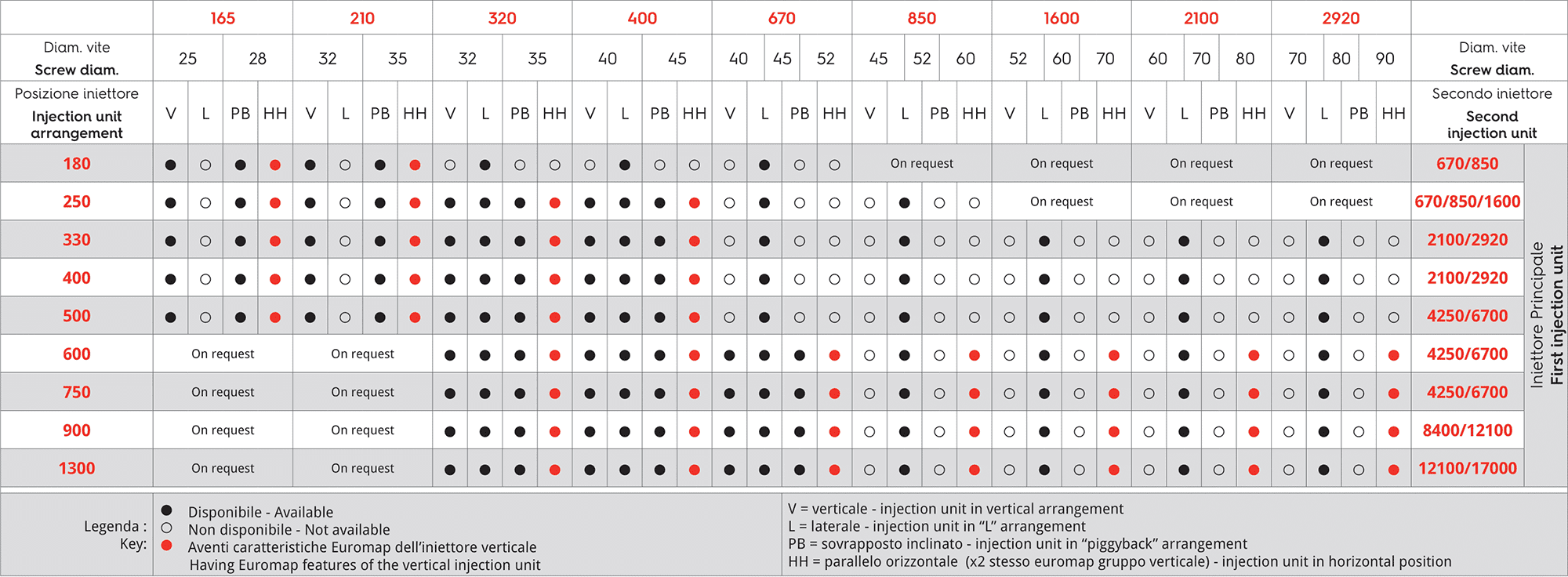

Multi-component machinery of all sizes and configurations to better meet your needs. Whether it is 2 or 8 units, vertical, horizontal, parallel or piggyback we have engineered the modules and power packs in order to meet your needs.

Configurations

Features

AMICO 4.0

All Negri Bossi machines are prepared, as standard, for the activation of our patented Amico 4.0 wireless or wired interface. This enables easy connection to our Remote Service Network. Amico 4.0 provides customers with remote technical assistance, often enabling immediate resolution of the issue. Should a service intervention be required, initial remote analysis means the engineer can arrive with the correct parts and information, to quickly resolve the problem. Amico 4.0 will provide a true Industry 4.0 solution and activating the package 4.0 will also provide machine monitoring and easy access to online software upgrades. Clamping force auto-correction and closed loop feed throat cooling are part of the present self-adaptive processes and ongoing collaboration with our suppliers.

Controller

MOTUS TOUCHSCREEN CONTROLLER

The NOVA range is equipped with Motus, the first ‘True’ Multi touch Controller. Features include:

- Innovative gesture navigation system incorporating swipe, scroll & zoom functions

- Virtual object for axis movement based on gesture orientation (Patent Pending)

- Modern, slim design with smartphone familiarity

- Customizable interface to personalise screen and functions

- Sequencer to create special cycles

- Quick search function for parameter editing, graphical editing and analysis

- New functioning modes, “step” and “in production”

- Smart alarms function for improved fault management

- 21.5” Colour TFT LC multi-touch display with a 1920X1080 resolution

- Power Link bus connections based on Real-time Ethernet technology

- Data transmission is safe, noiseless and faster with < 2 ms communication speeds

- RFID (Radio-frequency identification) for external access

Applicable Models

APPLICABLE MODELS

|

|

|

NOVA sT

|

|

BIPOWER

|

|

VECTOR

|